Smarter Process Control for Consistent Quality and Maximum Recovery

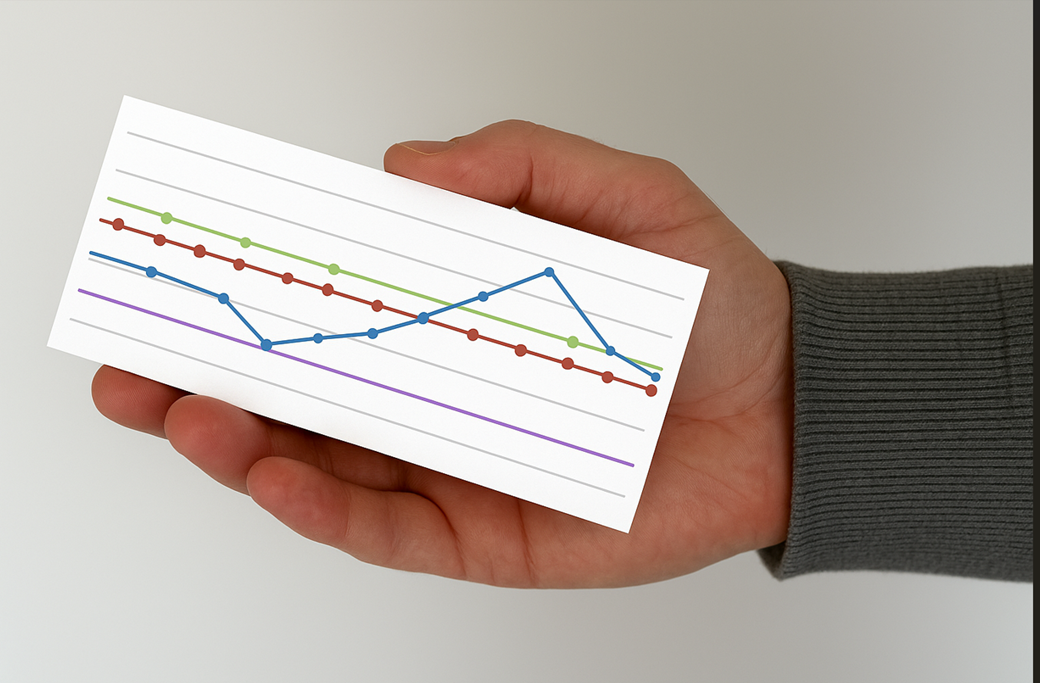

In modern food processing, meeting customer specifications isn’t just important—it’s essential. Producing products that are too high in quality or outside the desired specifications can lead to unnecessary costs or create unrealistic customer expectations. The goal is to consistently produce on spec—within the Acceptable Quality Limit (AQL). But knowing when and how to adjust your process is key.

RP Potato support

Process control

Simple Control Parameters for Complex Processes

RP Potato Support helps you take control of your processing line by implementing straightforward quality control parameters such as:

• Dry matter content

• Sizing

• Recovery rates

We also offer real-time trending dashboards that visualize quality metrics across the entire production process.

Integrated Data for Smarter Predictions

By combining data from multiple sources—such as Celox sizing systems, peelers, optical sorters, and QA sample points—we help you predict final product quality before it’s too late. This allows you to proactively make adjustments and consistently hit your quality targets.

Integrated Data for Smarter Predictions

By combining data from multiple sources—such as Celox sizing systems, peelers, optical sorters, and QA sample points—we help you predict final product quality before it’s too late. This allows you to proactively make adjustments and consistently hit your quality targets.

Managing Complexity in Large-Scale Operations

In large processing facilities, the number of control parameters can be overwhelming. It often takes years of experience to manage the process effectively. Even then, critical issues can slip through due to the volume of data—resulting in off-spec production or unnecessary losses.

Automation and AI-Powered Support

That’s why RP Potato Support partners with HAI Automation to offer:

• Predictive analytics

• Real-time alerts

• AI-supported decision models

These tools empower operators to make timely, data-informed adjustments and prevent costly deviations.

Preventing Loss Through Real-Time Action

When a quality attribute crosses the Upper or Lower Quality Limit (UQL or LQL), recovery suffers. Timely interventions can prevent this. Our alert systems—delivered to operator screens or mobile devices—ensure immediate action. Meanwhile, management can review interventions, analyze root causes, and implement long-term improvements.

One Platform, Total Control

Using the HAI Data Cloud Platform, we combine and visualize all data from across your operation—giving you a comprehensive overview and full process control from start to finish.

Scalable Solutions for Every Level

Whether you’re looking to implement basic control monitoring or advanced AI-supported models, RP Potato Support has the tools, expertise, and flexibility to help you maximize quality and recovery—at any scale.